RBSL Company conducts trials with its TITAN AVLB

07-Jun-2020

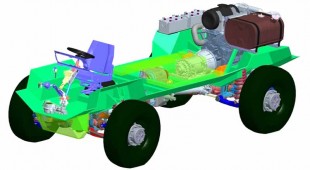

According to a Tweet released by RBSL (Rheinmetall BAE Systems Land), the company conducts trials with the British Army at Albemarle Barracks with the Titan Armoured Vehicle-Launched Bridge (AVLB) to enhance performance and user experience even further. The vehicle is based on the chassis of the Challenger 2 Main Battle Tank (MBT).

Rheinmetall BAE Systems Land (RBSL) is a UK-based combat vehicles design, manufacturing and support business. As a Joint Venture, RBSL combines Rheinmetall’s military vehicles technology and products, with the capabilities and products from BAE Systems including Trojan, Terrier, Warrior, military bridging and the AS90 self-propelled artillery system.

The Titan AVLB is a new armored bridge launcher tracked vehicle based on the chassis of the Challenger 2 MBT (Main Battle Tank) to replace the old Chieftain AVLB (Armored Vehicle-Launched Bridge) in service with the British army since 1986. The bridge launching system is mounted on the top of the hull. It can carry and lay the current range of In-Service No 10, 11 and 12 Close Support Bridges, providing ground maneuver formations with improved operation of the bridges enabling them to be laid in a greater range of terrain conditions.

In two minutes, the Titan AVLB can launch the N° 10 bridge system which has a length of 26 meters and wedges can lay multiple combination bridges in depths of 5 meters, and over bridge oil pipelines and bridges. It can also carry two 13.5 meters No 12 bridges, which are laid in only 90 seconds.

The TITAN AVLB for the British Army has a crew of three including a driver, commander, and operator. It has a combat weight of 62,500 kg and can run at a maximum road speed of 59 km/h with a maximum road range of 450 km. For its self-protection the vehicle is armed with a 7.62mm caliber General Purpose Machine Gun.

The Chieftain AVLB is basically a Chieftain MBT chassis without a turret and fitted with a hydraulic system for laying and recovering a bridge.

The bridge of Chieftain AVLB is carried folded and is launched over the front of the vehicle. The hull-mounted hydraulic pump, which is driven from a Power Take-Off (PTO) on the main engine, operates five cylinders arranged to launch the bridge in three manually sequenced stages. The bridge girders and launching structure are made of high-strength nickel-alloy maraging steel developed by the International Nickel Company. The deck and kerbing are of weldable aluminium alloy. The No 8 tank bridge is 24.4 m long and is made up of two tracks, each 1.62 m wide, with a 0.76 m centre gap between. Each track is divided into four parts, two toe pieces each 4.55 m long and two centre-pieces each 7.6 m long.

In March 1984, Vickers Defence Systems was awarded a contract by the British MoD (Ministry of Defense) to convert 11 Chieftain Mk 1/4 gun tanks into Chieftain Mk 6 AVLBs. The conversion work included removing the complete turret and replacing it with an armored roof plate with a commander's hatch; fitting armored lugs for mounting the launching mechanism on the hull and roof plate to maintain the same geometrical position as on production AVLBs; installing the hydraulic bridge-launching mechanism; stripping the vehicle and refitting the driver's/crew compartment and external parts to accommodate the AVLB components; modifying the hull to accept the HD1400 constant running pump installation; manufacturing the maraging steel launch structure; and providing mounting points at the front of the hull for the Pearson Engineering Track Width Mine Plough system, which was already then in service on Centurion Assault Vehicle Royal Engineers.

Source: armyrecognition.com